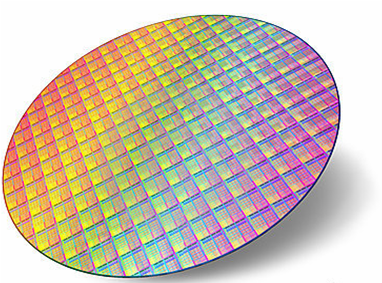

Package Capability-Frontend

- Wafer backgrinding

- Wafer size: 8 or 12 inches

- Final thinned thickness: min 50um

- Final thinned thickness tolerance: ±10um

- Wafer sawing

- Different chunk tables with vacuum available for different wafer size

- Use DI water with CO2 and Diamaflow to avoid ESD, contamination issues

- Different blade types and optimized parameters for different wafer materials (like Si, Cmos, LiTaO3, glass)

|

|

- Die to reel capacity

- Six sides inspection(missing bump, crack, breakage, contamination, etc.)

- UPH: 12~14K

- Min die size: 0.3mm*03mm

- Die material: Si, SiGe, GaAs

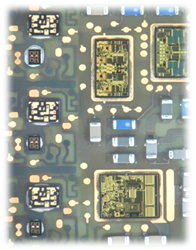

- High accuracy surface mounting technology

- Fine pitch copper pillar and CSP flip chip

- High placement accuracy(tolarance ±36um) with automatical adjustment function

- High accuracy of mounting force control

- High efficiency of fully automatic optical inspection; 100% AOI, can detect all surface defects such as missing component, tombstone, wrong polarity, shift, short, contamination, etc.

|

|

- Die attach capability

- Multiple die: multiple different dies/mutiple epoxy types

- Thin die capability

- Stack die capability

- Die attach with film

- Flip chip capability

- Solar chip capability

- High efficiency of fully automatic optical inspection; 100% AOI and it can detect all surface defects such as missing die, shift, rotation, short, epoxy on die, etc.

|

|

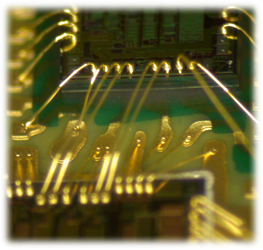

- Wire bond capability

- Wire distance: 35um

- Wire bonding accuracy: ±2um

- Cu wire and other alloy wires

- Wires on stack die capacity

- Super low loop wire capacity

- QFN capacity

- High efficiency of fully automatic optical inspection; 100% AOI and it can detect all surface defects such as missing wire,

shift, rotation, short, epoxy on die, etc.

|

|